Index

- What is a biomethane plant?

- Biomethane plants: risks and pollution

- Biomethane plants in Europe: overview and growth

- Authorization for biomethane plants: regulations and requirements

- How much does a biomethane plant cost?

- Biogas vs biomethane: what are the differences?

- Why choose an agricultural biogas plant with Sebigas?

What is a biomethane plant?

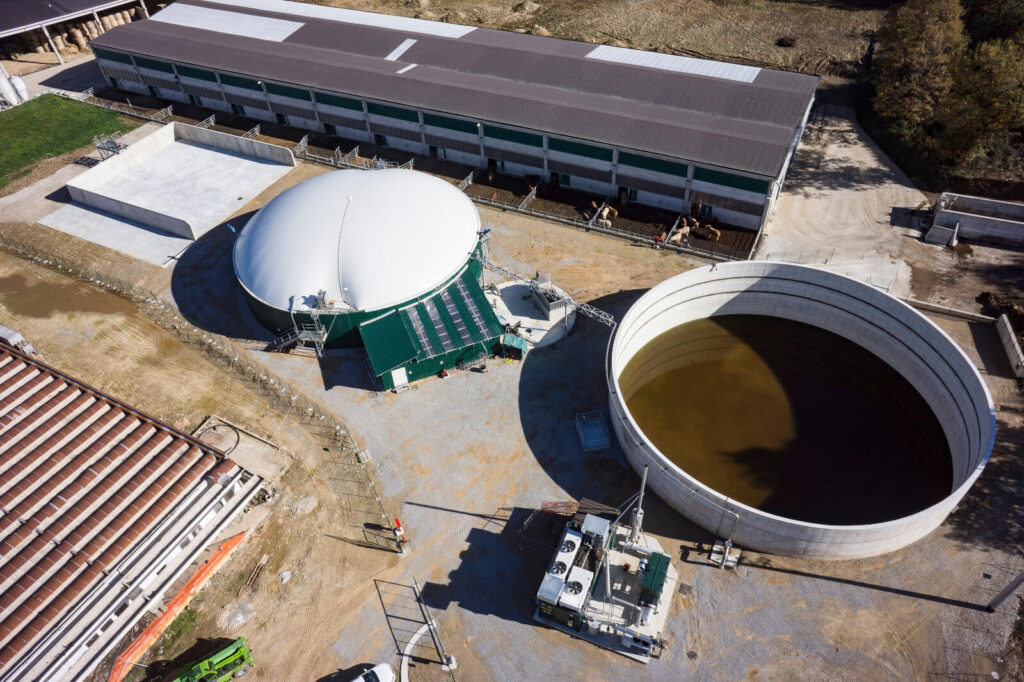

Biomethane plants are a sustainable and profitable solution for renewable energy production. Biomethane is a gas obtained 100% from renewable sources through a purification process (upgrading) of biogas, which is generated via the anaerobic digestion of organic matter.

The biomass used to feed biomethane plants contains a high amount of organic material degradable by anaerobic bacteria.

In biomethane plants, raw biogas undergoes an upgrading treatment, which involves the removal of impurities and the separation of methane from all other components. The goal is to achieve a minimum CH₄ concentration of 95% and to meet the required quality standards.

The most commonly used biogas purification technologies in biomethane plants include:

-

-

- Membrane technology;

- Water scrubbing;

- Chemical absorption;

- PSA (Pressure Swing Adsorption).

-

Biomethane plants: risks and pollution

Biomethane plants do not contribute to greenhouse gas emissions or air pollution. Instead, anaerobic digestion prevents the disposal of biomass in landfills, where its natural decomposition would generate greenhouse gas emissions.

The plants are designed to minimize odor production, but their management depends on several factors, including:

-

-

- The type of biomass used;

- Storage and transport methods;

- Implemented odor control technologies.

-

To mitigate potential odor emissions, solutions such as covers for pre-tanks and final tanks, as well as anti-emission covers for slurry storage tanks, are used. These measures reduce gas emissions and prevent their dispersion into the atmosphere caused by wind.

Biomethane plants in Europe: overview and growth

Biomethane plants in Europe are experiencing rapid growth, driven by the EU’s push for decarbonization and energy independence. With strong policy support under the Renewable Energy Directive (RED II) and national incentive schemes, the number of operational plants has steadily increased across member states.

In 2024, Europe boasts 1.548 biomethane production facilities, marking a significant increase from previous years. According to the European Biogas Association (EBA), combined biogas and biomethane production by the end of 2024 has reached 6.4 bcm/year.

Authorization for biomethane plants: regulations and requirements

The authorization process for biomethane plants in Europe varies Country by Country but generally involves compliance with EU environmental and energy regulations, including permitting for emissions, land use, and safety standards. Developers must obtain several approvals, such as environmental impact assessments, building permits, and grid connection agreements. In many EU countries, streamlined procedures have been implemented to simplify and accelerate the permitting process. Additionally, access to financial incentives often requires compliance with national renewable energy targets and sustainability criteria.

How much does a biomethane plant cost?

To determine the cost of a biomethane plant, an accurate project assessment is essential, considering various technical factors. The cost depends on the plant size, the type of biomass used, the upgrading technology, and the connection works to the national gas grid. Only through a detailed study and an economic-financial analysis of the project is it possible to accurately determine the investment value and its financial sustainability.

Generally, the cost of a greenfield biomethane plant between 200 and 500 smc ranges from €8 to €15 million, including civil works, upgrading system, and grid connection.

Biogas vs biomethane: what are the differences?

| BIOGAS | BIOMETHANE |

| Gaseous fuel produced through anaerobic digestion of biomass. It consists of 50–70% methane (CH₄), 30–50% carbon dioxide (CO₂), and other impurities such as hydrogen sulfide (H₂S). It can be used for electricity and heat generation via cogeneration systems. |

Gaseous fuel obtained from the purification (cleaning and refining) of biogas and composed of at least 95% methane (CH₄). It is a sustainable alternative to fossil natural gas and can be injected into the natural gas grid or used as a vehicle fuel (bio-LNG or bio-CNG). |

Why choose an agricultural biogas plant with Sebigas?

Choosing to design and build an agricultural biogas plant represents a strategic investment. With nearly twenty years of experience in biogas plant design and construction, Sebigas stands out as the ideal partner to deliver reliable, efficient, and tailor-made solutions.

Relying on Sebigas means choosing a company with proven expertise, capable of designing plants for farms of any size. The customized approach starts from the mass balance phase, with a detailed analysis of the energy yield of the available biomass. This process allows the optimization of biogas production, ensuring maximum plant profitability and a favorable economic return over time.

Moreover, the selection of the best technologies available on the market makes it possible to configure a highly efficient plant, optimized to ensure stable operation with reduced operational and maintenance costs.